Welcome to the website of Yinglai Tech

0086-315-5919026

Liufuming@intelligentlaser.cn

Welcome to the website of Yinglai Tech

0086-315-5919026

Liufuming@intelligentlaser.cn

以客户为中心 以技术为核心

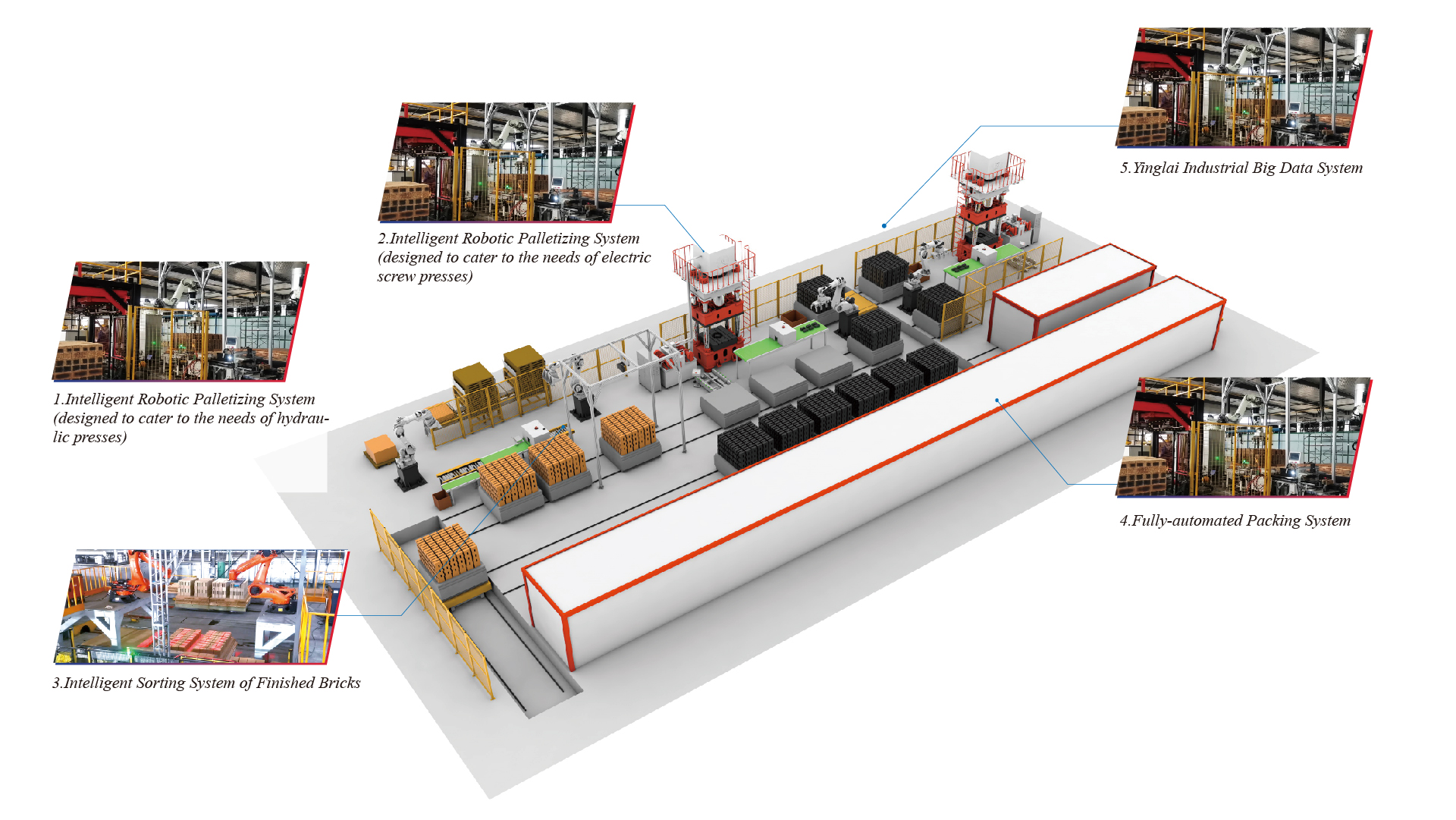

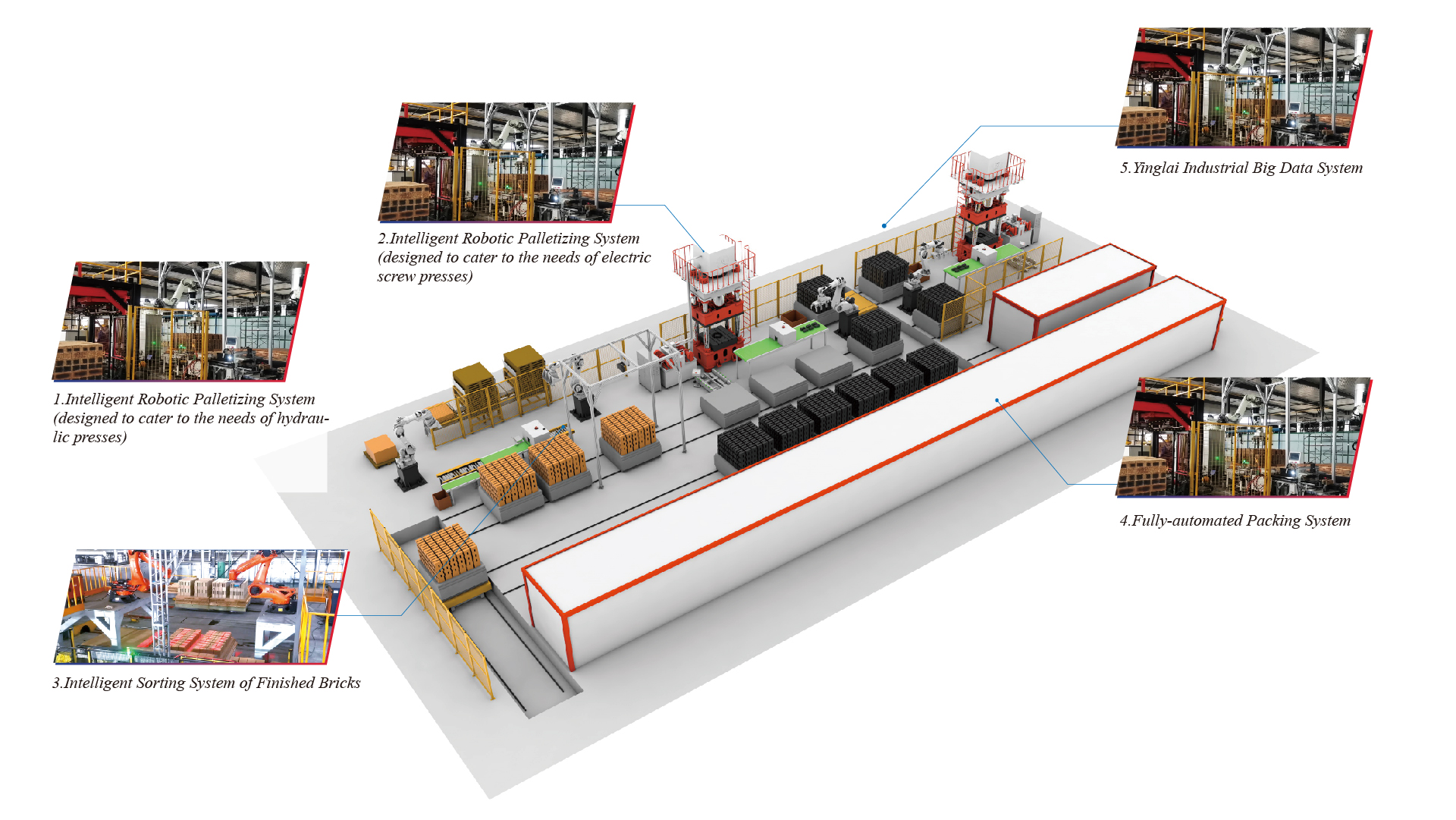

Customized production lines can be provided as per the specific needs of customers and without changing the existing site-layout.

The intelligent production line of burnt bricks mainly includes:

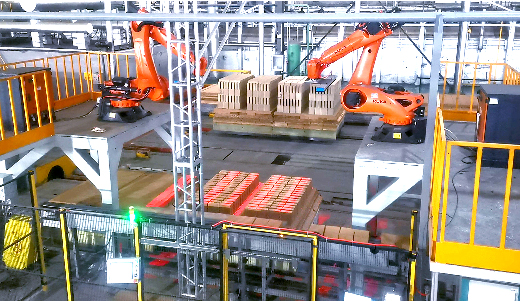

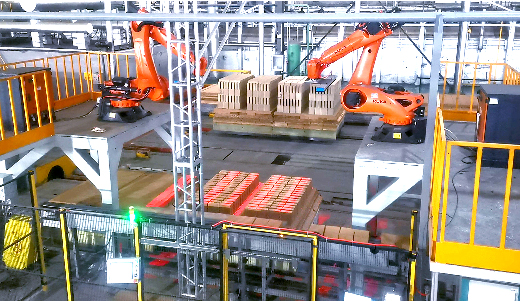

1.Intelligent Robotic Palletizing System (designed to cater to the needs of hydraulic presses)

Enable automated cleaning, code printing, labeling and weighing for the semi-finished bricks

Intelligent Kiln-cart Shuttle System (compatible with both automated palleting and manual palletizing)

Full-process intelligent solution starting from initially moulding to finished products.

Benefits Analysis:

40%-50% reduction in personnel required

30%-40% increase in overall production efficiency

5%-10% reduction in energy consumption

以客户为中心 以技术为核心

Customized production lines can be provided as per the specific needs of customers and without changing the existing site-layout.

The intelligent production line of burnt bricks mainly includes:

1.Intelligent Robotic Palletizing System (designed to cater to the needs of hydraulic presses)

Enable automated cleaning, code printing, labeling and weighing for the semi-finished bricks

Intelligent Kiln-cart Shuttle System (compatible with both automated palleting and manual palletizing)

Full-process intelligent solution starting from initially moulding to finished products.

Benefits Analysis:

40%-50% reduction in personnel required

30%-40% increase in overall production efficiency

5%-10% reduction in energy consumption

Technical Support:Yinglai Technology

Technical Support:Yinglai Technology