MgO-C Bricks

Full-process Intelligent Solution for the Production of MgO-C Bricks

Customized production lines can be provided as per the specific needs of customers and without changing the existing site-layout.

Customized production lines can be provided as per the specific needs of customers and without changing the existing site-layout.

The intelligent production line of magnesia-carbon bricks mainly includes:

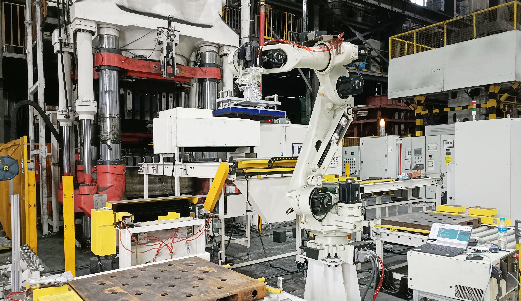

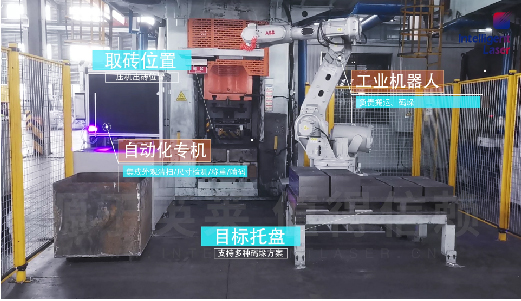

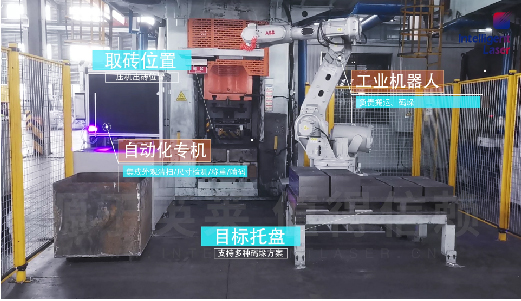

1.Intelligent Robotic Palletizing System (designed to cater to the needs of hydraulic presses)

Enable automated cleaning, code printing, labeling and weighing of semi-finished bricks.

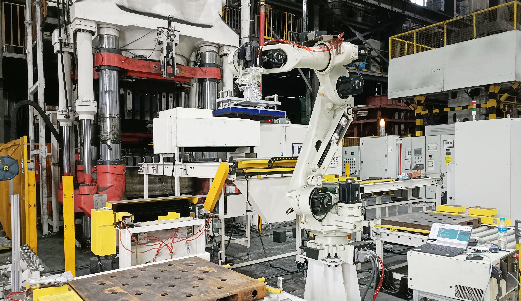

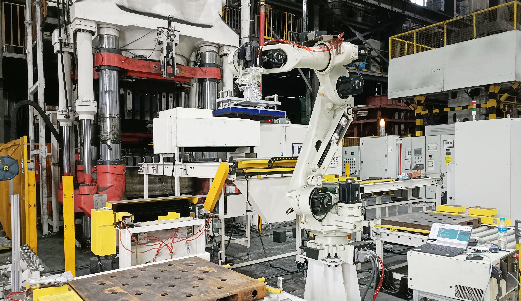

2.Intelligent Robotic Palletizing System (designed to cater to the needs of electric screw presses)

Enable automated inspecting, cleaning, code printing, labeling and weighing of semi-finished bricks.

3.Intelligent Transfer System equipped with AGV

Customized dimensions available with maximum load of 3 tons.

Enable automated pallet pickup and delivery with features of magnetic stripe navigation, automatic obstacle avoidance and automatic charging.

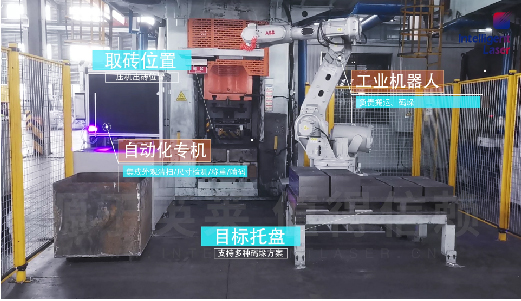

4.Intelligent Robotic Depalletizing and Palletizing System

Intelligent pallet recognition with 2D vision.

Robotic depalletizing and palletizing with 3D vision.

Enable simultaneous depalletizing and palletizing operations of multiple brick types.

Enable continued depalletizing and palletizing operations with irregular intervals.

5.Automated Packing System

Intelligent wooden pallet shuttle system.

Automated bottom-film placing & sealing-film wrapping.

Automated banding with PET strap.

6.Yinglai Industrial Big Data System

Automated data acquisition system, information identification and tracing system, as well as centralized production line control system.

Automated data acquisition system, information identification and tracing system, as well as centralized production line control system.

Full-process intelligent solution starting from initially moulding to finished products.

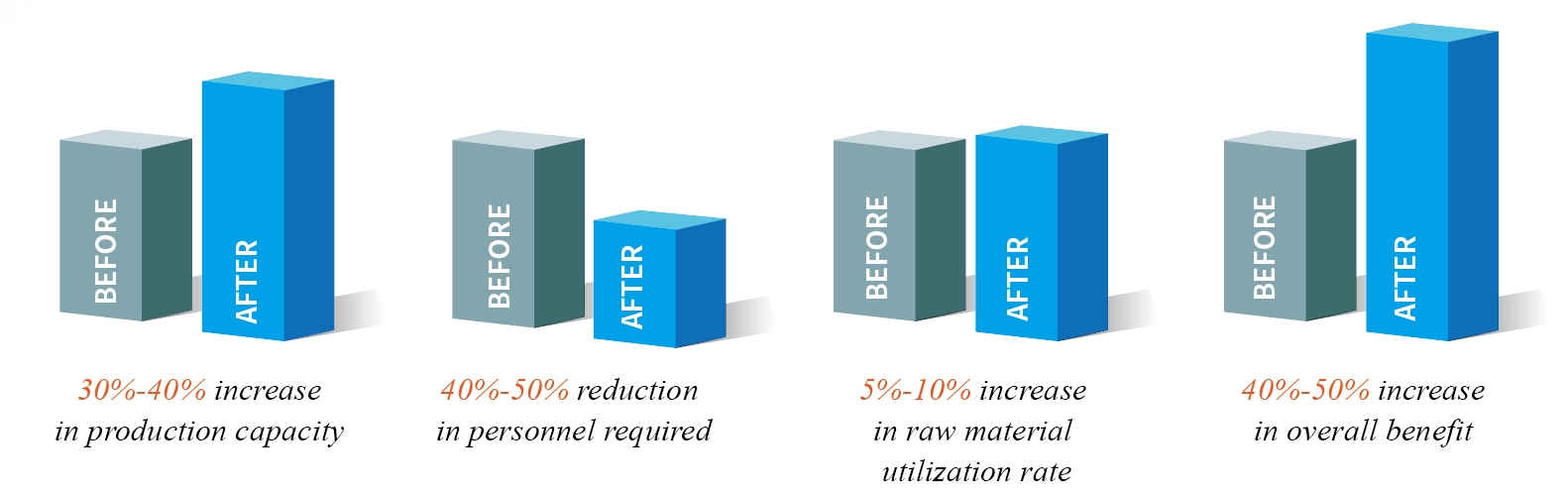

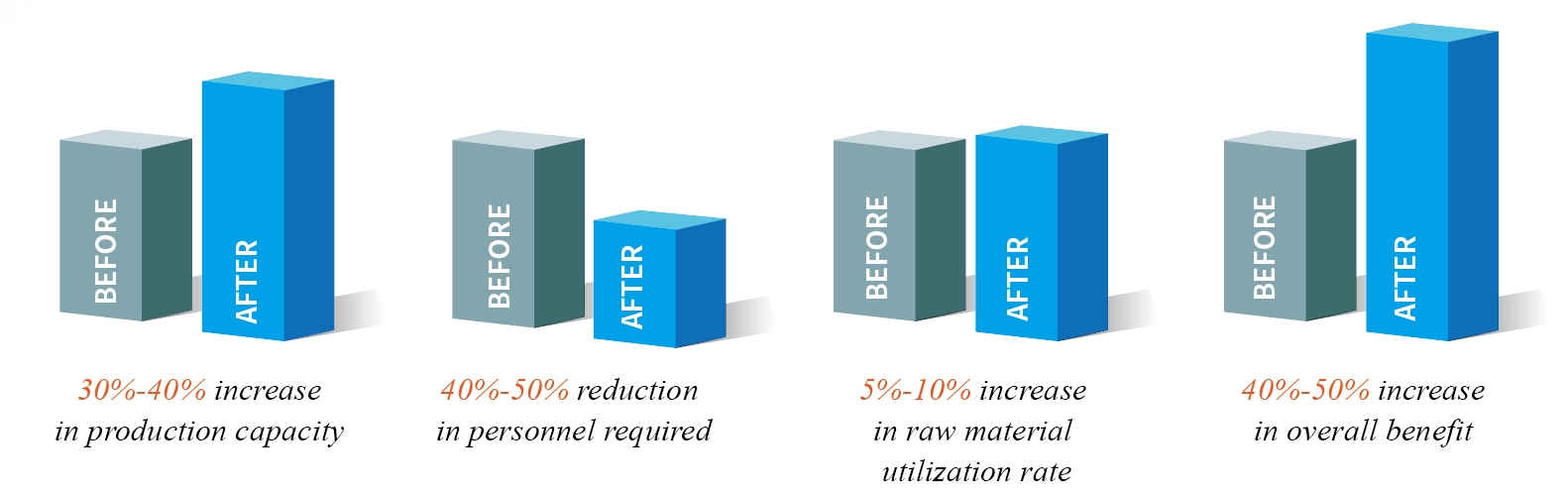

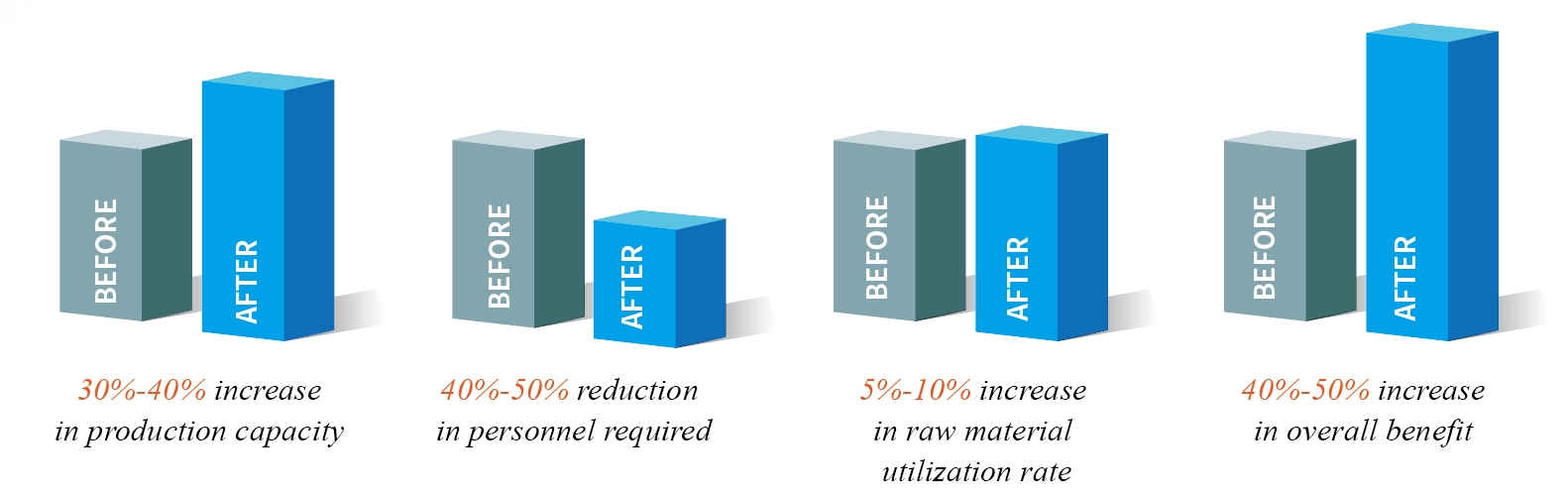

Benefits Analysis:

40%-50% reduction in personnel required

40%-50% increase in overall production efficiency

5%-10% reduction in energy consumption

▲Full-process Intelligent Solution for the Production of MgO-C Bricks

▲Full-process Intelligent Solution for the Production of MgO-C Bricks

▲Full-process Intelligent Solution for the Production of MgO-C Bricks

▲Full-process Intelligent Solution for the Production of MgO-C Bricks

▲Intelligent Robotic Palletizing System for MgO-C Bricks (Designed to cater to the needs of electric screw presses)

▲Intelligent Robotic Palletizing System for MgO-C Bricks (Designed to cater to the needs of electric screw presses)

▲Intelligent Robotic Palletizing System for MgO-C Bricks (Designed to cater to the needs of hydraulic presses)

▲Intelligent Robotic Palletizing System for MgO-C Bricks (Designed to cater to the needs of hydraulic presses)

▲Industrial Big Data System

--------------------------------------------------

We offer a comprehensive range of services to meet the diverse needs, including R&D, engineering, production, installation, commissioning and maintenance, etc.

Tel: 0086-315-5919026 / 15232687601

Technical Support:Yinglai Technology

Technical Support:Yinglai Technology